MAKING INNOVATION HAPPEN

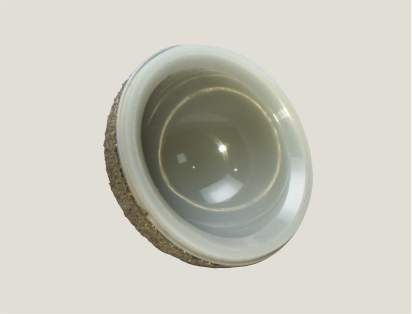

DIRECT COMPRESSION MOULDING

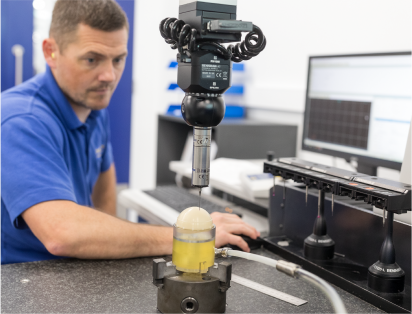

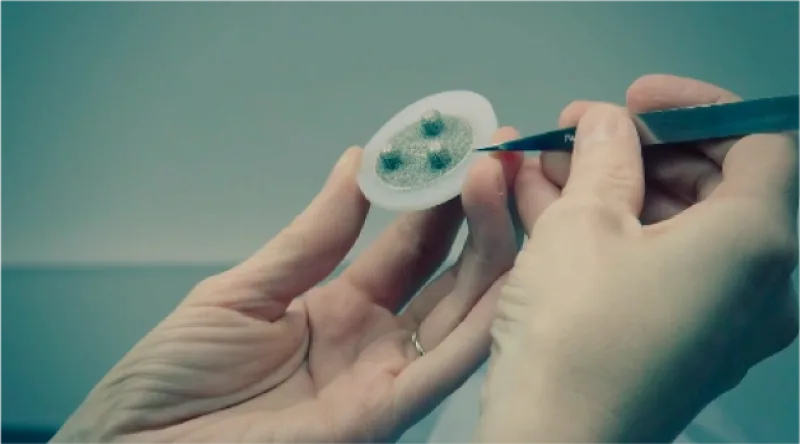

Orthoplastics has focused on advanced methods of manufacturing UHMWPE and is now a World leader in Direct Compression Moulding technology. Using our technological expertise we can bring to market new innovative product solutions to address failure modes typical within orthopaedic implants.

Contact us